Current:Home >> About carefree >> Technical Capabilities

Technical Capabilities :"Realise Design Through Technical Capabilities"

In a world dominated by mass production products, CareFree provides custom solutions to customers challenges.

Envision: We utilize brainstorming techniques, fish bone diagrams, 8D and other analytical tools to develop design concepts.

Plan: Our project engineers will utilize the most effective project management tools to capture, plan and monitor your project during the development process.

Design: With over 40 years of combined experience in caster design and development, we ensure all objectives of each application are met.

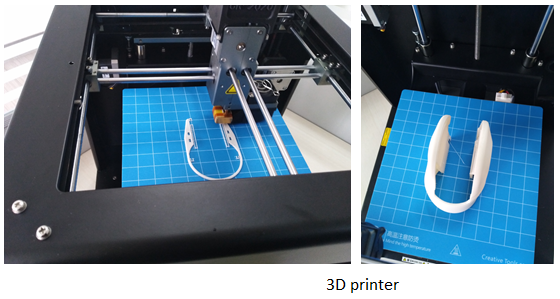

Develop: with access to state of the art equipment and supplier base, we produce prototypes and samples to fulfill the design plan and meet customer needs.

Test: Extensive and stringent testing provides assurances to the customers and validate design integrity.

Release: After customer testing and approval, the new designs are released to production.

Design: "Performance and Quality Starts with Good Design"

CareFree Casters engineering team has the capabilities to produce 2D drawings, 3D models and FEA studies and rapid prototyping.

We are happy to provide our customers with 3D models in many CAD formats like ACIS, IGES and STEP.

To ensure that our design and development process is intact, we follow 6 steps in our development process flow. Some of the requirements include the development of a Project Charter, establishing DFMEA (Design Failure Mode and Experimental Analysis), PFMEA (Process Failure Mode and experimental Analysis), testing and verification, validation and optimization processes to ensure that product meet the objectives.

Manufacturing: "Flexibility to meet Customers' Needs is one of our Corner Stones"

In addition to our in house assembly and testing expertise, we have the capabilities and accessibility to a wide supply base that covers a multitude of processes including molding, precision machining, stamping, forming, casting and plating.

We pride ourselves on developing the processes and tools required to provide quality products.

Quality: "At CareFree Casters, Quality is both a Philosophy and a Way of Life"

To our customers, CareFree name is synonymous with quality, reliability and performance.

We devote time and money to ensure consistency in our products by training our employees, using reputable materials and suppliers, developing controlled manufacturing processes and committing to a sustainable environment.

Testing: "Validate the Integrity of our Products"

We test our products constantly to the highest standards compare to the industry standards such as EN-12527 and IEC 60601. Life cycle, endurance, mobility, shock and vibration are some of the regular tests we perform to ensure highest of quality associated with Carefree Casters name and products.

CareFree Casters and wheels are tested to ensure they pass all the standards and specifications set by customers in the approval process. Some of our testing capabilities are:

1. ENDURANCE

To validate the integrity and strength of the caster or wheel under specific load requirements. This test is performed by rolling the caster assembly or wheel dynamically and repeatedly over a predetermined bump height at various speed and time intervals.

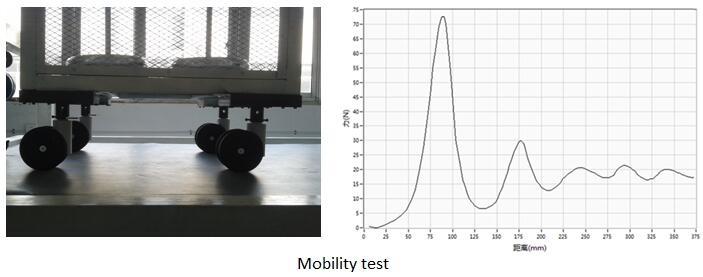

2. MOBILITY

To measure the forces required to start, roll and swivel a cart under different floor conditions. This test is conducted using a specially designed and manufactured cart. The cart is tested on a variety of floor conditions depending on application, standards or customer requirements. The start, roll or swivel forces are measured and recorded.

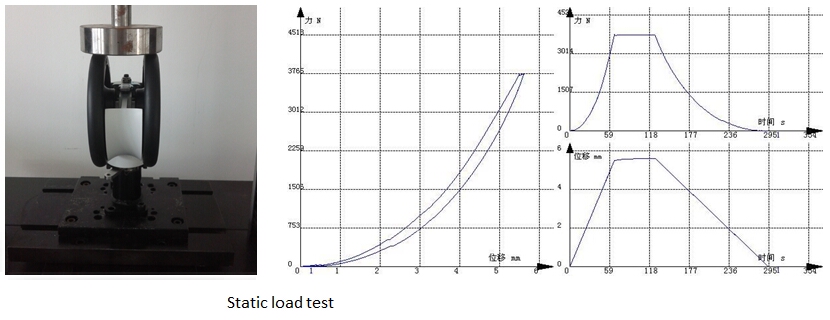

3. STATIC LOAD TEST

To demonstrate the maximum load the caster can sustain without damage, casters and wheels are placed under a pre-determined load over a time period. Casters and wheels are inspected for damage after the load is removed.

4. BRAKE TEST

This test establishes the forces required to engage and disengage the brake as well as measuring the forces required to rotate the wheels while the brake is applied.

5. BRAKE CYCLE TEST

This test is performed by repeated cycling of the brake mechanism. The wear of the brake components and its effect on the brake force is measured and documented.

6. BRAKE RAMP TEST

To determine the maximum ramp angle that a loaded cart with brakes engaged would hold for a period of time in forward, backward and sideward directions.

7. DROP TEST

To verify the caster or wheel design is appropriate for the application. The cart with the appropriate casters and load is lifted to a required height and then dropped. The casters are checked for any damage. The testing is repeated according to the specific requirements.

8. OTHERS

Additional testing such as hardness (15N, Rockwell C, Shore A and D), hardness profile, shock absorption, chemical analysis, bond integrity, tensile and elongation are conducted as required.

Terms & Conditions | Warranty and Returns

© 2017 CareFree Casters. All rights reserved.